My thoughts on the Pfaff Quilt Expression 4.0 after one month

I purchased the Pfaff Quilt Expression 4.0 on 8/12/08 and immediately started using it. I do all my piecing and binding on the machine (quilting on a Mega Quilter) and so far it has done 15 quilts and started piecing #16 (holy cow!). For reference sake, my previous machine was a Pfaff 2134. There was nothing wrong with the 2134 but since I was doing so much quilting, some of the features that the 4.0 had made it very appealing.

Pros

— Dual lights. Especially since I do so much of my sewing in the evenings.

— The presser foot can be controlled by the foot pedal.

— IDT (previous machine had it too but is definitely a plus if you’re coming from another brand)

— Needle down/foot up option. Great for chain piecing and appliqué.

— Large foot pedal. Never thought this would be a pro or con, but it’s actually really nice.

— I like the tie-off style of this machine better than the 2134.

— Low bobbin indicator. The 2134 had one but never worked properly.

— It cuts your threads for you!

— Dual tension plates for the needle thread and bobbin thread. If you’ve ever wound a bobbin without taking your needle thread out first, you’ll appreciate this!

Cons

— Sewing with the included 1/4″ foot is horrible.

Problems include:

— fabric is ‘eaten’ by the machine at the beginning of every seam

— fabric tends to veer off to the left (leaving you with 1/8″ or 1/16″ crooked seams)

— the machine has a hard time sewing over thick seams (think the middle of a kaleidoscope or while attaching binding strips when you have binding+backing+batting+top with seams). The IDT doesn’t help and you have to tug a bit by the back of the machine to get it over the hump.

— The top fabric tends to bunch and become unaligned with the bottom fabric (even with IDT).

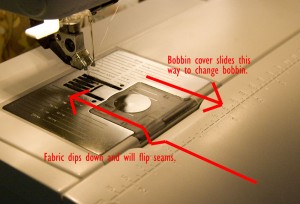

— The bobbin is top loading. That alone isn’t really a problem but they designed the bobbin cover so that it could be removed without removing the free-arm part but in the process of that, they made a dip right before you reach the needle and it will flip all your seams that you have so neatly arranged (hopefully that all makes sense).

— Second thread spool holder is not nearly tall enough (that’s pretty minor but I usually sew with two spools of thread – one going to the needle and the second to wind bobbins so I don’t have to rethread every time.

Ok, so yes, those are some pretty significant cons.

The bobbin cover just downright annoys me. I’m hoping they’ll come out with a table that I could use instead (or perhaps a new free arm?). Honestly, I would have preferred to remove the free arm to change my bobbin than how they did it. When you have you seams set and then they go through this hump/dip they flip. Every time. This is however a deal-withable problem.

The stitching problems are just downright ridiculous BUT THERE IS AN EASY FIX!

Basically, you need to buy a new 1/4″ foot. I’m not sure if the style I bought 2 years ago for the 2134 are still made but I certainly hope so. Sean and I both examined the feet and cannot see anything that would make the foot that comes with the machine stitch so badly. But it does. I pulled the old 1/4″ foot off of my 2134 and all of these problems disappeared. Put the new foot back on and all the problems reappeared.

Some pictures (please pardon my linty cutting mat). You can click on them for larger versions.

The bobbin dip.

The styles are different but none of these changes seem like it would cause these problems.

I oversharpened the next image to make sure the stitches were visible (I should have used black thread!). In the fabric on the left the machine initially ‘ate’ the fabric and then tried to recover and the fabric veered to the left. I never could hold and guide the fabric to prevent this. The fabric on the right when straight in and has even stitches. Both of these were fed in in the needle down/foot up scenario since that’s how I feed almost all of my fabrics for chain piecing.

—–

So that’s that. Why does the foot cause so many problems? Really, I have no idea. I think it’s rather silly to have to buy an additional 1/4″ quilting foot for a quilting machine to stitch properly. But at least it’s fixable right?

Hopefully I got all my pros and cons in. I’m sure there are more so feel free to ask questions if you have any.

_______

UPDATE! January 2009

I’m still having a horrible time with this machine. Fabric is still being eaten, though not as often since I switched feet. It still doesn’t sew straight. Whenever I go over a thick set of seams (not huge, but quilts get like that sometimes, ya know?) it doesn’t go over them and the stitch length regularity is horrible. The thread cutter is horrible. It keeps telling me there are jams when there are no jams at all. I’ve disassembled everything when it does this and there is never actually a jam. You just have to sit there and press the middle button over and over until it finally lets you sew. So frustrated. I wonder who I could sell it to? I truly have buyer’s remorse at this point. I figured it just had some quirks and I would get used to them but this is totally unacceptable for a Pfaff at this price.

_______

RANDOM NOTE: August 2011

I have moved past this machine. I stopped using it, bought something else and am done with the mess of the QE4. I’m happy to leave the comments open to let everyone read and discuss as they please, but I don’t have much interest at all in participating (Hopefully that doesn’t sound grumpy! It’s not intended to be. Promise. 😉 )

393 thoughts on “My thoughts on the Pfaff Quilt Expression 4.0 after one month”

Comments are closed.

Thank you for the EXCELLENT info on the QE 4.0! I am relieved I am not the only one with the fabric eating problem. glad to know my old foot will fix things right up.

I hope you sent your well written comments to Pfaff. They need to do some adjusting! And I agree–the bobbin bugged me, too.

Kim

I have the Expression 4.0 and love it. I have had “no” problems. Most machines eat fabric at the beginning, I have not seen one that does not. I don’t have that problem with my Expression 4.0, but my Pfaff dealer and I spent an afternoon with my machine, and she would just hold the thread to begin the stitching and we did this on several different weights of fabric and none of them were eaten. Give it a try. And one of my most favorite features was the check button that clears a jam! What a time saver when you are machine quilting!!!

Emily,

Thanks so much for this great review. I’ve been trying to decide between this machine and the Bernina 440. I’ve tried them both out extensively, but I still can’t decide which one to get. I haven’t seen any reviews on this machine, so your review is very helpful.

I never had any problems with the fabric getting eaten up with the 1/4″ foot when I tried out the Pfaff QE 4.0. Maybe there’s something wrong with your machine or it needs to be tweaked or something. I would definitely bring it in to your Pfaff dealer and have it checked since it’s still under warranty. Or maybe there’s something wrong with the 1/4″ foot that came with your machine. For that much money, I’d be very ticked off if that happened to me. I didn’t try sewing anything with pressed seams, so I don’t know if they would flip like they did for you, but that would really annoy me, too.

Thanks for all the great info. I’ll have to try sewing through a bunch of layers like a quilt sandwich with binding to see how well it does. And I never noticed if the fabric veered to the left. That’s all really important info to know before buying such an expensive machine.

I was wondering if you knew if there was a way to disengage the auto presser foot lift that goes up halfway each time you stop sewing so that you can control the presser foot with the knee lift. Sometimes I’d like to be able to control the foot manually without the foot going up on its own all the time.

I haven’t sent it to Pfaff but I’m going to. I just haven’t had a chance to go find an email address. There is nothing wrong with the foot that we can find from looking at it. It doesn’t appear to be a machine problem since it does fine with the other foot. I thought I was just going crazy with these things happening until Kim mentioned she had it happen too. I haven’t used the knee lift but I know you can turn off the foot up feature in the menu.

I also own the Pfaff Expressions 4.0. I’ve had similar problems and this is what I have used for fixes. For crooked seams, I purchased the Pfaff 1/4 inch foot that has a metal guide attached to it. No more crooked seams. I also purchased a single hole needle plate to help prevent chewing of the fabric. And for the times when the bulky items just won’t move thru the machine, I learned to increase the pressure of the presser foot (it’s in the toolbox) and now things move along just fine! I hope this helps!

Thanks so much for your review. I’m also trying to decide on a new machine. I think I’ve narrowed it down to the Pfaff 4.0 and the Elna 7200. I’m really leaning towards the Pfaff as I really like the machine, the dealer seems more knowledgeable, and the support and service seems more readily available. I do wish I could find more reviews on it though which is why I’m happy I found this. Overall it sounds like you’ve been able to work through and find solutions for most of your “cons” and that the machine does have many positive features as well.

As for the machine eating fabric… I read somewhere online of someone else having the same problem. It turned out that the machine was not being threaded properly. The presser foot needed to be in either the up or the down position (sorry – I do not remember which way it was). There may have been another trick to threading as well. The other thing that helped in that case was to be sure to hold onto the top and bobbin thread when sewing the first couple stitiches of each seam. I’m not sure this info will be helpful for you as it seems you’ve been able to correct the problem but maybe it will help someone else.

Thanks again for all the info on the 4.0. Now to decide!

If you use the automatic thread cutter, the threads are too short to hold on to.

Using the right foot keeps the fabric from veering off to the left, I think.

Thank you Sue! I will definitely look into those and try them. I wish you could get accessories without having to go to dealers.

Julie, I will always quilt with a Pfaff because if the IDT. I know a walking foot accessory would basically be the same but those are so bulky. Overall though, the machine is great and a pleasure to sew with.

responding to Veronica:

You can turn-off the auto presser foot lift in the toolbox. Then you can control the presser foot with the knee lift.

Peter,

I e-mailed Pfaff about disengaging the auto presser foot lift (the one that goes up halfway each time you stop sewing so that you can pivot) and they sent me a reply back that you can’t disengage it. When I was at the Pfaff dealer, a salesperson and I tried to turn it off in the toolbox. Even after we turned it off, it still kept going up halfway. I tried using the knee lift with the auto foot lift turned off, too, and it still kept going up halfway, which kind of defeats the purpose of having a knee lift. So I’m guessing it can’t be turned off. I’m wondering if it’s just the regular presser foot lift that you can turn off (the one that goes up all the way to the top).

Thank you so much for your review. Across the world from you, in Norway, I’m trying to decide wether to buy a Pfaff Exp. 4.0.

I never had a Pfaff before. The machine I have now is Husqvarna Sapphire 870 quilt. I’m very happy with it but I like to change sewing machine when something better comes along. I’ve hadde the same problem with my Husqvarna eating fabric. I’ve found out that it happens sometimes after using the automatic thread cutter, because the thread jumps out oft place.

Are you mostly pleased with your Pfaff or is there too many cons and frustrations?

Joana

Veronica, I was able to turn it off completely so when you stop sewing the foot and needle do stay down.

I’ve had the machine eat fabric in chain piecing too so there were no loose threads in that scenario. Overall I am pleased with the machine (now that it’s not eating fabric!).

Emily, I tested it again today and I was able to keep the foot down, but when I used the knee lift, I couldn’t control the height of the foot. It kept wanting to automatically go all the way up. When I use a knee lift, I like to be able to control the height of the foot so that if I want to pivot the fabric just a little and want the foot to come up a tiny bit, I can do it with the knee lift. But it doesn’t look like you can do it with this machine. I still love it, though, and am planning on buying it. It’s the my favorite machine out of all the ones I tested.

Do you know if they still make the old 1/4″ presser foot like the one you have? I wonder if you can still buy them from Pfaff dealers.

I haven’t used the knee lift with any of my machines but now I must admit I’m totally tempted to try it. 😛

I haven’t looked at what feet are currently for sale at the dealers. If the stores don’t have them anymore, you could probably find one on ebay.

I’ve found that lot of times when you are trying to get the 4.0 to do something, and it continues to do different than what you want, just simply shut the machine off, wait a few seconds and then turn it back on. I’ve had instances where the presser foot would raise every time I stopped sewing – even if I hadn’t selected the needle down position. That was so annoying. But by simply turning the machine off and waiting a bit, it seemed to reset itself.

My dealer offers pfaff classes and if you take one, you can get 20% off all accessories. That helps a lot on the costs of the feet. You could check with your dealer and see if they have that type of promotion.

Just wanted to add that there are cutouts now for the 4.0. The sew-steady portable table http://www.dreamworld-inc.com/ and the sew perfect table

http://www.sewperfecttables.com have written me this week to let me know they do indeed have the pattern now for this machine. The slanted front on this machine drives me insane! I am constantly dropping my sewing stuff! Has anyone used a sew-steady table? Does it feel high to your arms when you are sewing?

Has anyone used the portable tables? I haven’t had any problems with the slant on the front. I love my sewing table so I’m not sure I want a new one.

I use this portable table for my Bernina, and I´m very happy about it.

http://www.sezeziusa.com

I think I´m going to buy the Pfaff QE 4.0. Thank you for your comments about your 4.0.

Emily, I have so much trouble with the slant because this is the first time I’ve had a machine that has a slant and is not sitting in a cabinet. My previous machine sat flush in my sewing cabinet. The 4.0 doesn’t fit in my cabinet so now I am in search of a new one. Can you show me a photograph of what yours looks like?

Mia, I couldn’t get your link to work but I think I figured it out. Is it

http://www.seweziusa.com ?

Emily, when I tried this machine out, I noticed that when I stitched a long, straight line, I couldn’t see each individual stitch. All the stitches ran together like one long stitch. I didn’t like that and when I asked the lady at the Pfaff dealer about it, she said you can never see each stitch unless you change the color of thread so that the top and bottom threads don’t match. I know this isn’t true because my machine that I have now (Janome) shows each stitch when I have the same color thread on the top and bottom. So I was wondering if you noticed the same thing as I did with your machine. I’m wondering if this is a Pfaff thing. Every other machine I have sewn on in the past has stitched with each stitch separate from the next (with matching threads), which is the look I like. I think it looks more professional when you can see where one stitch ends and the next one starts.

Sue, I whrite wrong link, but you find the right.

Sue — My sewing table is just our old kitchen table. It’s solid oak and doesn’t vibrate with the Mega Quilter and serger going at top speed so that’s why I’m in love with it. I’d love to have an inset machine table (or whatever they are called) but I want heavy-duty solid wood (and something that looks pretty too) and that’s just not in the budget. You can see it here (with the old machine):

http://carolinapatchworks.com/blog/2008/05/22/where-i-work/

Veronica — I can definitely see individual stitches on the 4.0 and 2134. It sounds like a tension problem maybe? I agree though, it looks much better with individual stitches.

Oh, and just a random note, all comments with links automatically go into moderation due to huge spam problems. So if your post doesn’t show up immediately don’t worry.

Thank you so much for this review! I’m finally getting around to purchasing a computerized sewing machine I think the Expression 4.0 is going to be it! I plan on quilting on it too so the large harp is a huge selling point!

Your work is just beautiful. When you do your top quilting you have the viking long arm quilter and what table are you using? You had pictures of two tables and Quilters and said the one was nothing but trouble. So just which one do you use of the long arm and the table. I ask because I am thinking about getting the Pfaff grand quilter and a table and a new program that is out called Qbot by inspira. It does the top quilting for you it is really cool but costly. Would like hearing back from you.

I don’t use the Mega Quilter on a frame. I just set it on my sewing table like a normal sewing machine. I originally wanted the frame that Viking/Pfaff sold and had the Voyager frame for a short time but returned it because of the horrible sewing machine. I thought about getting the qbot but it was quite expensive (and the frame and cruise control must also be purchased) and it seemed limited in features for the price they were charging. I can easily do a queen quilt in my current set-up so I’m happy with that.

I, too, have recently purchased a Pfaff Quilt Expressions 4.0 after quilting for 12 years on a 1475. I’m having a lot of problems with the automatic cut device especially cutting the bobbin thread. It works intermittently then not at all. This especially occurs when free motion quilting. I take off the tacks at both ends (obviously) as well as the automatic cut and use the manual cut key and it still doesn’t work. Other problems include: using my stitch in the ditch foot which has to have the needle position offcentered from the usual 0 (in the exact middle of the foot) to a 3 to force it to actually stitch in the ditch; when free motion quilting, it skips stitches, makes grinding sounds whenever using batiks, and does not accept good high quality threads(King Tut, Mettler, YLI, etc.) whenever changing from one to another. I’ve tried changing needle sizes and types, using all different weights of threads, rewinding bobbins, rethreading the machine, cleaning bobbin case, rechecking settings repeatedly. I’ve reproduced these problems on my dealers demo machine. Anyone else experiencing similar problems?

I have just purchased the 4.0 and am having the same problems with free motion quilting – cotton thread shredding and breaking, skipped stitches and bad tension on both top and bottom

dealer had same issues on my machine and her store machine – I notice your posts are from several years ago and problems still exist – I may have to return it

Gloria, Oh my! It sounds like your machine is out of alignment somewhere. Has your dealer offered to replace the machine or send it in for repairs?

I’ve read a lot of forums on this machine and I have never heard of anyone having the above problems. Have you had these problems since day 1 of ownership? What does your dealer say about all this?

That doesn’t sound normal at all. I did have some stitch skipping today for the first time. Thread cutting works most of the time. I haven’t done any free motion and I mostly use Aurifil.

Gloria, I was just curious where your 4.0 was made. They were being made in Sweden and I just found out that they are now being made in China. I just bought mine yesterday. Unfortunately, I’ll have to wait until the middle of next month to get it because the 4.0s are backordered from the Pfaff factory in China. I was kind of leery about buying one when I found out about that, buy my Pfaff dealer assured me that Pfaff will still maintain the strict standards they’ve always had. I’m still kind of nervous, though. I hope I don’t have any problems with mine.

Interesting Veronica… I checked the bottom of mine and it was made in Sweden.

I checked with my dealer today and she said all the Pfaff Expression machines are being made in Sweden. The Pfaff Select Machines are now being made in Shanghai, China.

Hmmm. I wonder if my dealer got it wrong. Although, she worked for Pfaff for 10 years and has a close relationship with them, so I’m inclined to believe her. Maybe there’s still hope for my machine to be made in Sweden (got my fingers crossed!). I’ll have to ask her about it the next time I talk to her. Thanks for the info.

My 4.0 Expression was made in Sweden. A friend bought the same type from the same dealer a couple days before me and has had the same troubles and even more so when changing threads. Hers rebels but cuts the threads more often. Our dealer has called Pfaff a couple times, made their suggested adjustments (some worked and some made the problems worse), he has torn her machine apart and is now in the process of putting it back together and will test run it tomorrow. I’m waiting to see how hers runs before taking mine in. Meanwhile, I’m not using it at all as it is too frustrating. Thinking of just asking for a new machine if simple adjustments can’t be made to make it right. I’ll be sure it is made in Sweden. Free motion quilting seems to be the downfall on both our machines and the floor model. Tried out the 2.0 and it also skips stitches and won’t cut 100% of the time on free motion quilting.

Thanks for the comments, gals. Will let you know how it turns out in a couple days.

Any news on the free-motion problems? I just bought the 4.0 and I’m very accomplished free motion quilter and I can’t get the machine to free motion quilt well at all. It skips stiches every few inches and then the upper thread breaks. I’ve tried all the normal fixes I would tell my students to go through…new needles, threads, etc. I can’t believe Pfaff would release a “Quilter’s Edition” with a new free motion setting and not test that it would actually free motion quilt! That would be a major blunder. I’m hoping someone has found a solution…my thread cutter works fine thankfully. Thanks! Darlene

I don’t use the 4.0 for free motion so hopefully someone else can chime in! There seems to be a lot of things that were not tested on this machine IMO.

I found that the free motion stitching was awful and I couldn’t get it to look nice at all, so I’ve sent it back and a grand quilter is on it’s way 🙂

Thanks for your comment Sarah, I have just purchased a QE4, and it works fine in all respects but today I tried free motion quilting, and I can’t seem to get the tension right. The bobbin thread seems to be too slack. I have tried trying to adjust the tension in the menu, but this makes no difference.

Any suggestions from anyone, also I don’t like the free motion foot jumping up and down whilst quilting. Is there any way I can stop it doing this, and just hovering over the fabric?

However, the 10 inch space is great for large quilts.

Hi Jenny, You can tighten the bobbin tension. It doesn’t tell you this in the manual but you take off the needle plate, remove the small grey plastic piece closest to you and remove the bobbin case. On it there’s a black screw that takes a flat screwdriver and you turn it anti clockwise maybe only quarter of a turn. However while this improved my normal stitching the free motion was still rubbish. Maybe you’ll have a bit more luck. I just decided to return it as I already have the 2058 so only wanted the extra space for quilting. The grand quilter isn’t here yet and I’m getting impatient! I’ll get back to you about the foot going up and down in free motion mode as the 2058 does the same but I haven’t tried to turn it off before. Hope this was helpful.

Hi Sarah, and many thanks for your comments, I will definitely try the bobbin tightening technique. If I discover how to stop the foot jumping up and down I will let you know. Free motion quilting is a pain with any machine, I think it is a question of perseverence and trial and error. Do you find the 2058 is a good free motion quilter? I have a cheapee Brother machine and although it is a bit involved to set up, the free motion quilting is good, although the throat space is very small, so no good for large quilts.

After spending so long deciding which quilting machine to buy, I shall be disappointed if I can’t crack this.

I will let you know how I get on, if at all!

Yes the free motion stitching is great on the 2058 which is why I thought the expression would be the same as most of the functions are very similar. I don’t think that you can stop the foot going up and down as you cannot operate the foot function whilst in free motion mode. You get used to it though, I find it’s Ok if you set the needle to stay down when you stop. I love my 2058, I just can’t do big quilts on it. I thought the expression had it all, but now I think I’ll be better off with the two machines instead, the 2058 for piecing and the grand quilter for quilting.

The foot going up and down is somewhat necessary — if it doesn’t, the quilt will come up with the needle. You can turn it off though for thread painting type sewing — it’s in the menu — something like Sensormatic? I have the other machine on the table right now, but I can check the name tomorrow when I switch. It goes up and down on the mega quilter but when you get it going fast enough you can’t really even notice.

I use two machines as well. It works great. 🙂

Hi Sarah, I thought long and hard about buying the Grand Quilter instead of the QE4, but as I understand it, it only does straight stitching, which of course is all you need for free motion quilting. I am interested in applique on quilts, so need the satin and blanket stitch as well. I thought the QE4 would be all that in one machine, which it is.

I am sure I will get used to this system in the end, but I wish I could sort out the tension problem. I will keep on tweaking! I am determined to get there in the end.

Any thoughts on my tension problem Emily?

Recently I purchased a new Pfaff Expression 4.0. Within a day I realized that the sewing machine would not do free motion quilting without skipping stitches and not always cutting the thread. All other operations seem to work good. I have done a lot of quilting on a Pfaff 7570 and it has always worked good in the free motion operation. I returned the sewing machine to the dealer a few times without the problem being resolved. About a month ago, the dealer sent the machine back to the “Pfaff experts”.

Today, I tried to get my money back from the dealer without success. They said that they would “replace it when they get some in” without knowing when that will be. Now, I’m out the money and the defective machine.

I’ve lost a lot of confidence with Pfaff.

I have found that the Expression 4 will not free motion quilting. The thread breaks, needle breaks and skips stitches. Every time I return my machine they find that i am doing something wrong. Will not take machine back or resolve issue. Bought the machine for quilting not just sewing. Some thread cannot be used on this machine.

Would they replace it with a different machine? I changed mine for the grand quilter and still use my 2058 as well. It seemed a good idea to get one machine that does it all but the expression doesn’t seem to live up to expectations. Changing the machine for another the same might not help you as loads of people seem to have trouble with the free motion. Good luck with getting it sorted!

Jenny… I would love to hear how you make out with free motion quilting on the 4.0. I’ve never done it before so couldn’t try it out prior to bringing home my machine. Now I’ve been so busy with other projects that I still haven’t tried it. Thanks!

Julie… Well, I am gradually getting there. With the Spring free-motion engaged in the settings menu Page 2:16 in the manual, and reducing the thread tension to around 4.5 (will differ with different threads and needle sizes) I use a needle with a large-ish eye as the thread will be whipping through the needle at a fair rate – Topstitch around 90 or 100. Also use the speed control to get a constant speed when you press your foot pedal. Move the fabric around smoothly preferably with quilting gloves (or thin gardening gloves – a lot cheaper!) to give you some grip on the fabric. Go easy and steady and it should work. Practice makes perfect though, don’t give up. Your first attempts will probably look a bit ‘spikey’ but will get smoother with practice. Good luck!

Very interested to read the opinions and review here- I have a Quilt Expression 4.0 on layby at present-not far from paying off. During my test drive I quilted a wallhanging, bound the quilt, used decorative embroidery threads and decorative stitches, stitched button holes in cotton and poly thread, tested some applique stitches, ditch quilted, outline quilted and did a tonne of testing of different threads for FMQ on about 4 batting types, and a little strip piecing. I was very impressed and have bought it to do custom domestic quilting of very large quilts. I have a Mega quilter which I use for my FMQ and adore, and a Pfaff 2027 which is being replaced by the 4.0 as it is really just too small for doing big quilts easily.

I asked about the gobbling issue and the dealer said-which seems very logical really-that the reason this can happen esp. on fine fabrics is the 9mm wide slot for decorative stitching is just too wide for fine straight stitching with no wiggling. Solution is to use a straight stitch throat plate so there is no space for fabric to be gobbled up into.

There are many, many variants in tension issues and every machine I have ever used personally or for a customer’s quilt, or any student’s machine I’ve ever played about on, must be tweaked for the exact combination of batting, thread and fabric. It is just like adjusting the stitch length or stitch style…and we all do that without fear or worry. Learning to FMQ and to adjust tension can be frustrating but is necessary if we want to get good results from whatever machine we are using. I guess for people having issues, after consulting the manual, make the most of the dealers out there who know how to get the best from their products they stand by and sell. And of course, occasionally, lemons are produced on factory production lines, which may need tweaking or adjusting, or replacing with new machines if truly faulty. At least Pfaff are a good company to deal with in this regard.

Oh yes, the contributor who mentioned issues of threading the machine as the cause of tension problems, but couldn’t remember which way to put the presser foot-either up or down, is absolutely right- it is important that any machine, when being threaded, has the presser foot at full up position to open up the tension disks. Then once threaded, and the foot is lowered, the tension disks close around the thread and hold them in position. So if you thread the machine without lifting the foot right up, it is impossible for the thread to actually engage with the part of the machine that controls much of the tension that is applied to the thread. Hope this makes sense.

I know that there are two free motion modes in the 4.0, one for the sensor foot, which goes up and down at slow speeds then lifts up for clearance at high speeds, and another mode to accomodate the free motion spring foot-which where I live is not included as standard, but can be purchased. The idea here is to choose the foot that gives you the best results, since FMQ is demanding on a machine and there are so many variations possible in fabric and thread, and batting choices.

For those of you having trouble, it could be combinations of battings, fabrics, threads, needles, threading process and the foot chosen to FMQ with-so try the other foot if you have it. It may give you more control and eliminate the skipped stitches that some of you have been experiencing.

As to the China manufacturing, I have been assured that Pfaff are making the Quilt Expression 4.0 machines still at the Huskqvarna location in Sweden-and the box label on my machine confirmed this. The lower end smaller Pfaffs are now being produced from China however, in Shanghai.

I am really looking forward to getting my machine home- and putting it straight to work. My feeling was that I have purchased a very solid and easily adjustable machine that is capable of high quality stitches on a variety of combinations. I do hope that those of you out there with issues are able to happily resolve them and enjoy your lovely machine.

I just got my QE 4.0 two days ago and I really like it a lot. I haven’t had time to really test it thoroughly and put it through its paces, but I think I’m going to be very happy with it. I tested the free-motion quilting and I think it does a pretty good job. I haven’t had tension problems with it so far.

I do think I’m going to get the single stitch throat plate and the 1/4″ foot with the metal guide. My Pfaff dealer told me about a Quilter’s Toolbox that she’ll be getting and she thinks it’s supposed to have these two items, plus a a larger free-motion quilt foot that doesn’t come with the machine. The toolbox also has an 18×24″ clear extension table, quilting needles and a free-motion guide grip. Does anyone have this toolbox? Here’s a photo of it: http://www.pfaffusa.com/2714.html The picture of the 1/4″ foot doesn’t look like it has a guide on it to me. I’m wondering if they have the wrong picture up or if this is an older Quilter’s Toolbox. My dealer said Pfaff just came out with a new Quilter’s Toolbox for the QE 4.0.

These 4.0 machines definitely are being made in China. Mine says Made in China on the bottom of my machine. Some of the Pfaffs (like the Select models) are still being made in Sweden or the Czech Republic. The 4.0s are being made in China under the strictest of quality controls in factories that were already owned by Pfaff. So I’m not worried about my machine (knock on wood!).

Stephanie… I read you comments with great interest. Very informative and educational.

I have had my QE4 for about 3 weeks, and have FMQ a large quilt very successfully, using YLI cotton. I tried to do a little more decoration with YLI Fine Metallic, and oh my, it kept skipping stitches, and made a horrible graunching noise in the bobbin mainly when it took up the thread. I realise I have probably got the tension wrong, or perhaps I should have wound the bobbin a little looser. It was my first attempt at metallics.

I had YLI 50’s cotton in the bobbin, and used a metallic needle.

Any advice or ideas as to how to do the FMQ as successfully with mettalics?

Ah Jenny,

I haven’t used YLI fine metallic, but the only really successful high speed metallics I have used are made by Superior and come on a large cone.

Nearly always metallics run without trouble if you work upside down and wind the thread at low speed, onto the bobbin. Then quilt with the backing facing up. You can ditch stitch before you go to work upside down, just be sure to mark any directional lines in first so you know which way is up, when working on the back.

Also you can try to lower the tension, use a topstitch or even jeans needle, not a universal, and don’t thread the last threadpoint just above the needle. That is where a tonne of fray will happen. Sew slowly and all should be better than it currently is for you right now. Also well worth your time to make/borrow/buy a thread stand. The $9 sort seem to work 99% as well as the $90 variety from what I’ve experienced. Keep at it and experiement. You may prefer a finer thread in the bobbin if using metallic on top, something like The Bottomline works well for me.

About the previous post by Veronica, perhaps the 4.0’s had the early editions made in Huskvarna, Sweden, as mine says on the box, and then later production runs switched locations of manufacture? I know Husqvarna used to make their Sapphire in Sweden but are now making them in Shanghai… and Pfaff and Husqvarna and Singer are owned by the same company. Also you are right, so long as the quality control is extremely tight we shouldn’t need to worry-the parts are all genuine and not generic to my understanding, so the quality is much higher.

I am itching to get mine home, making good progress paying the beast off!

Stephanie, yes you are correct about the earlier models of 4.0s being made in Sweden. I think they switched later this year to being made in China. My dealer sold her last one made in Sweden a month before I got mine.

Hello, I have just purchased the 4.0 and set it up yesterday. I did a little experimenting with it yesterday. All of the stitches I tried were just beautiful. (By the way, it does say on the bottom that is was made in China.)

Anyway, I tried free motion with the included floating foot. The first try went well. After that the thread kept globbing up on the bottom. One time the machine stopped and I got an error message. I didn’t get a chance to try again today, but will persevere. I have 6 months of free classes from my dealer, so will make a list of issues and schedule a lesson after I’ve had more time playing with it. I certainly have high expectations for this machine and hope the problems have simple fixes. I also have the option of exchanging within 3 months for full value to an upgraded machine. Does anyone have experience with the Creative Vision?

Happy stitching. Thanks for this blog.

Dianna

Dear Emily and more friends.

I live in Ecuador, sorry my English is very bad. Like you all, a have the Patch Work hobby and now I need to decide for a new machine, please help me to decide for the best choice. I need some very sure machine, easy to maintain, not to much computerizing, home size, well verified, not complicated.

Very thanks of your opinion and maybe your friends can also help me in this question, thanks, I wait for you answer, I am Elena

Emily,

I have finally got my QE4 home and have been piecing away and testing different presser feet. I think I may have information about why your old 1/4″ foot stitches better and more straight with no left-pulling.

my 1/4″ foot, like your new one, has a little bit recessed off the side. Your old one is straight and does not. The little bit of extra metal on your old foot more than likely catches the edge of the feed-dogs and gives balanced contact with both sides of the feed-dogs, where certainly my new 1/4″ foot does not. Most of the contact is on the left side, which explains the pulling to the left you (and I) have noticed. To use the new foot with the recessed part, I use a blunt quick-unpick, or you could use a rounded awl, nothing too pointy that could cut the fabric- to guide the fabric through straight. You can use it underneath to help smooth out any seams that get re-arranged, too.

Apart from that, something I found works well is to adjust the needle position to the right until it is your desired seam allowance from the edge of the foot O. Then both sides of the foot, which is wider than the new 1/4″ foot, are in contact holding the fabric down onto the feed-dogs. There is no pull with this method, but you loose your markings on the foot.

I am thinking about buying a spare foot or infact drawing or lightly etching in markings for 1/8 and 1/4″ behind and in front of the needle’s position, to help with setting in of patches. I will have perfection!!!

Maybe this is helpful to you?

I have just started working on a massive and heavy quilt for a customer- cannot believe how much room inside the harp there is! Infact I rolled up the whole quilt, which must have been about 102″, by folding and rolling, just to see if it would fit in there, and yes, it did, with room to spare! Awesome!!

Let me know how you get on. And thanks for starting this blog discussion, it has been useful to me and I suspect a whole tonne of other quilters out there!

Cheers,

Stephanie from Australia

That is a good point about switching to foot O and moving the needle. I will definitely try that. The space is really nice isn’t it!? When I sew my Jane blocks my scissors usually end up in that space. Heh…

You Dear Jane blocks are amazing. You are far more committed than I am to them. I have only done about 36 so far, since late 2000 when I was given the book. I have to decide whether or not to keep going: mine are in repros civil war fabrics, pretty.

I know what you mean about storing stuff in the space: I was piecing a tonne of four patches the other day and found myself stacking up pairs at the front and the middle of the harp, ready to sew! If you want to see come and visit my blog: it should register at your end with the details.

The current count of 4 patches is 470, a huge scrap busting exercise that has totally cleaned out the buckets of scraps, as it was intended to.

I am working on a great big quilt for a customer now, and hit my first little glitch- skipped stitches during FMQ. I found the control to lower the presserfoot pivot height of the sensormatic free motion foot, so there is less wiggle room for the quilt when FMQ. This totally solved the problem so I am once again a happy girl.

Love your blog! And Merry Christmas! Stephanie

Emily, I am so pleased that I found your Blog. I am on the verge of buying the QE4. I must make up my mind before December 31st, because my dealer is offering $500 off, or a free Fab-U-Motion w/Stitch Regulator. I haven’t decided which deal to take.

I am disappointed with what I have read here about FMQ. I thought that using the fabric mover, I would really be able to do a good job. Now I don’t know if I should even try.

Does anyone have any experience with the Fab-U-Motion? Does it really help, or is it a gimmick?

Janet from Merritt Island, FL

Hey All, I, too, just bought the 4.0 QE, again!

Like many of you, I rejected the first machine (dealer is still miffed) because it didn’t free motion quilt without skipping stitches. It quilted forward just fine but when I’d back down the spine of a feather or back down the line of feather plumes with an echo, it skipped stitches. Even after dealer gave it back “adjusted” it didn’t work. The problem seemed to be just with thicker thread–fine thread (Bottom Line or YLI silk) worked fine with 8 & 10 (60 and 70? sorry, don’t remember European #) Sharp needles.

Also I can’t see through or around the new sensormatic plastic foot. I can’t tell if I’m meeting a line of stitching or if I can back over something I’ve already stitched. Oh how I wish Pfaff would make an offset-arm foot like the Bernina folks have. Even an open toe metal foot like the Viking has would be helpful. As it is, I plan to have my foot drilled out with bigger holes and I’ll report difference and if successful, I’ll include pictures. I’ve ordered a few extra feet in case I massacre them trying.

After fretting over the machine I returned in frustration, I talked to the Flagstaff dealer, Odeggards (great guy!) about the 4.0 and he’s not had complaints and sold many. I was shocked. I don’t live there so didn’t buy from him. I phoned my dealer and said I’d try the 4.0 again. He’d sold the one I returned and would set up a new one for me to come in and try. (Said he sold it to someone who was just learning to FMQ.) So, I tried his new one with 14 topstitch (80?) needle and 40 wt. Superior Thread cotton thread; it couldn’t free motion quilt backwards either! I also tested 40 wt poly thread and it did better but not perfect. I switched to 16 needle and it worked ok. Thread mfg recommends 14 Topstitch needle with 40 wt. thread. Hmmmm. Tried other 14 & 16 needles (sharp, jeans denim, universal–all from dealer’s supply) and worked ok. Very little skipped stitches but some just the same. Is needle the problem?

This dealer decided if I bought this machine, it was mine for good. He’d not take it back. He took 5 min. to tell me this in no uncertain terms. I’ve not been back there.

I went to dealer south of here and explained situation; tried their machine and same problem! Store owner is a quilter and she insisted timing was off. She sent it to her tech and when she got it back, it purrs. It purrs for me, too. But the 14 top stitch needle seems to not work well. 14 new gold embroidery needle is fine. Metallica needle is fine. I’ll do more research on needles soon. Anyway, this machine is a dream. I use it for quilting and am working toward the Gaudynski/Schamber style of quilting–it must be precision perfect for me to be happy–and I am!

Sorry, I’ve not tried 1/4″ foot piecing. I’m coming from a 2056 which is an amazing, perfect machine. I kept it. I was looking at the new Bernina 820 coming out in a few days… but for many thousands of dollars less, I have every feature I wanted in a top machine and it’s light weight enough that I can take it with me if I want to. (New Bernina about 50 pounds)

Hopefully those of you who aren’t happy can find a good tech to do your adjustments. In my opinion, this is an amazing machine and I hope I don’t have to take those words back later. I did use it a lot over the last week and a half and I think it’s a sound machine. Dealer assures me she’ll stand behind machine and has my confidence.

Whoops, my bad! I have never posted on a blog before, and didn’t know that you shouldn’t use your last name.

I still want to know if anyone has any opinions on the Fab-U-Motion with Stitch Regulator for the QE4.

I purchased the QE 4.0 about a month ago and have experienced many of the same complaints as you. At first, it would break the upper thread while FMQ. I took it back to the dealer and the tech “tweaked” the timing and that has helped so much. Occasionally it will “throw” the upper thread from the take up lever. The dealer acknowledged that problem with the Creative Vision also but didn’t have a solution for it. I love the space, lights, thread cutter, pattern start so will continue to learn the machine and have more “tweaking” done if needed. My previous machine was a 2046. It just hummed along and never missed a beat but was limited in features.

One thing that’s helped me in spotting problems asap is wearing a pair of reading glasses even though my vision is really good (wonderful Lasix ? surgery). The magnification of the area where I’m sewing shows instant bobbin pop-up threads or when the top spool is bound up (for some reason). It lets me correct the problem before there’s a real problem. I’ve also had the thread kick out and not sure why.

Good Pfaff (industrial machine) tech over the weekend suggested I try to tighten up the top tension and see if the 14 Topstitch needle still skipped stitches. Not tried it yet though. He explained the topstitch needle has larger hole and kicks out a large loop for the bobbin hook to catch which it’s obviously missing. Higher tension would make smaller loop and maybe align it better with bobbin hook.

The modified metal open toe free motion quilting/darning foot works once it’s cut off at the top and the screw hole is drilled open down in the recessed part below the original screw hole. It’s wonderful to see around and works well with the sensormatic setting. Pictures available for anyone who is interested, let me know.

One thing though: the sensormatic setting makes an engine noise I find annoying that the spring motion foot setting doesn’t make on half speed. I like the quiet sewing on the spring motion setting better.

Hi LynnD

Would you mind sharing the picture of your modified foot? Thanks in advance!

Sure, I’ll shot pictures of it and post it on my webshots page for you. It ought to be up there in a day or so. It does work well with the sensormatic setting and does float just like the plastic (Pfaff provided) foot when free motion quilting medium to fast speed. Otherwise, it lifts and lowers like the plastic foot does. I always engage the needle down and that might be imporant, too.

You know I found that the skipped stitches can sometimes be a result of not adjusting the sensormatic foot low enough to the quilt. You will find an adjustment in the tools and setting menu-the little spanner and tool button- to allow you to lower the foot, I think it was called pivot height or similar. If for your batting choice and fabric combination you can still not get it low enough (for very thin ones), you may find the quilt is pulled up and down by the needle, a little wobble up and down, and this is what contributes to skipped stitches. Happened to me just the other day. Lowering the height helped alot but I was using Signature 40 weight and a 90 Quilting needle and still had the odd stitch skip. Quick call into the dealer and I found that the optional spring foot, with great vision and a nice big square foot to hold the layers more securely has totally eliminated skipped stitches. You can see much better with this foot I think. Just be sure you set up the machine for the different foot you wish to use (again in the tool and setting menu).

The reason Pfaff have given us both options is to get the best results possible with the best foot for the job, since quilting combinations of batting, thread and cotton (and needle can vary so much.

Cheers,

Stephanie.

Hi LynnD, Thanks, but could you please give me the web site details. I don’t see any links and I’m not too familiar with blog pages. Thanks again.

Shan

I’m very new at this type of communication, but I was so happy to find the review of the Pfaff QE 4.0. In the past I’ve pieced on a Viking D1, a cheapy drag to class Babylock, a Pfaff 2170 and a Pfaff 2056. The Pfaff, from the first stitch, has been my go to machine. I was always so happy with the way both of them fed, stitched, purred…..everything. No problems. Then I saw the 4.0. Had some of the features that I did like on the Viking D1, and I think the larger bobbin size was a key feature. After thinking about it for way longer than I usually do, I traded in my Pfaff 2056 and brought the 4.0 home. I also bought the single hole throat plate because that is what I always use when piecing. From the first stitch, I’ve been disappointed. It sounds like a tank, sews all wonky, and eats my pieces wether I start them a few threads past the red line or not. Emilys description of the problems she’s having are a duplicate of mine. I am planning on bringing it back in and having their service tech take a look at it. I’m also buying back my 2056. I’d like to stay in touch with this group and see what we can come up with as a cure. It may be little things, but it is not what you’d expect from Pfaff. Just not acceptable.

Happy New Year everyone. I too am very new to the medium of blogging and was very interested to come across this site. I recently purchased a QE 4.0 and did wonder from day one if I had chosed the right machine. Most of the features I am happy with however the problems I had were: missed stitches, cutter not always working, snarling at begining of sewing, having to re thread the machine often, the needle threader not working (and I’m as blind as a bat) and not happy with the quarter inch foot. When I purchased my machine, one of the questions I specifically asked the sales person was, “Why would you purchase this machine (QE4.0) above …..?” Her reply was it was made in Sweden.

Just two days ago I had reason to look at the base of my machine to find it was made in China! I was not a happy customer and took my machine back. I do believe the sales people I dealt with were totally unaware of this. They contacted the New Zealand agent and to cut a long story short I was given the demo machine, which was made in Sweden, and a cash back sum of money.

The boxes they come in are different. The Swedish made one has made in Sweden on it and the Chinese made one has German Design and nowhere on the box did it have made in China. As Pfaff has a long history I personally feel this is misrepresentation. Being a New Zealander and having knowledge about the Baby food scandel, which involved the NZ Fonterra Dairy Company, (who are a most reputible firm) I have very little faith in Chinese made products. I would be interested to know other peoples thoughts. I have yet to put my Swedish made machine to the test?

Cheers and Happy Quilting

I agree that it’s not up to Pfaff’s normal.

My machine was made in Sweden.

I left a message in the October time frame concerning skipped stitches, etc. The Dealer replaced my QE 4.0 with a new one. I tried it out before leaving the dealer and had the same problem with skipped stitches and not cutting the thread. After some discussion with the dealer I got my money back. I did a lot of shopping around and ended up with a Janome 6600. I have yet to have this machine skip a stitch, knot up or not cut the thead. I do have a 1 inch smaller opening but that’s a small sacrifice to have trouble free sewing.

I am glad I came upon this blog. I thought it was just my machine having problems. I just took it in for the second time since I purchased it with all of the stitching complaints you have mentioned. The first time I was having problems with it jamming every so often and I had to rethread top and bobbin to get it to work again with a good stitching tension wise. Then it got to a point that the bottom tension was always too tight. So brought it in and listed all my complaints (fabric eating, getting stuck when going over seams, jamming, tension etc). I got it back and the service report said they adjusted quite a bit. It seemed to work fine tension wise, but still ate fabric and had a hard time going over seams. I got the Motor blocked message a couple times for no reason. A bobbin thread jam message and no jam. Then one day while I was away from the machine pressing a seam, the machine started going by itself. The presser foot lowered and the needle started going up and down. The only way I could get it to stop was to turn the power off. It did this a couple times again on another day, so I brought it in yesterday to be serviced. I am about ready to ask for a different machine or my money back. After paying so much for this machine, it would be nice to at least be able to make one quilt without having any issues during the process.

This blog has saved me from a gigantic blunder. I was disappointed at my Janome 6600 and I was to trade it in for this machine. I have decided to wait two more years to allow Pfaff to get caught with its glitches. I am also more than bitter about having a machine made in China misrepresenting itself as European made. Europe needs these jobs- We need European craftsmanship. If we do not stand up to this abuse a whole culture of craftsmanship will be forever lost- to no one’s but China’s gain. So when Pfaff smartens up and does what it should, I would consider this model or the next one like it. I have a Pfaff 2170, Pfaff 7570, and these machines are exceptional and I love them to death. Honestly. The Janome 6600 has a wider throat but I have never bonded too well with it, since i like the Pfaff ‘feel’. The QE4 machine, to me, is not pricey. But to have to struggle with it – for whatever reason- is not the Pfaff way. Now, the Bernina 820 is worth too much. I say Pfaff should have charged 300 bucks extra and make sure the darn thing works. I am an urban legend- a professional who works 12 hour days and yet manages to sew. I do not, cannot deal with frustration, worry and twitchy equipment. Men would never tolerate a table saw with poor functioning. Why do we tolerate glitchy equipment? We are all too nice- we should boycott poorly executed, and hastily assembled machines. We deserve precision, sturdiness, quality and fine functioning in our machines. The only reason they are pulling this nonsense is because we are putting up with it. Both my Pfaff’s are made in Europe. That is what people buy when they seek a Pfaff. They are not getting my money until they clean up their act.

After trying two new Pfaff 4.0 machines at home and watching my dealer take out two 4.o machines right from the box and both could not be made to work either I demanded my money back and would not try another one “to make it right”. I bought a 6600 Janome and love it. Once again, quilting and sewing are fun not frustrating, there are not skipping or tension issues. the thread cutter works every time without fail and the free motion is wonderful. The Janome is much more straight forward and user friendly and the manual is very easy to read as well. I’m looking forward to doing more happy quilting and sewing and less time trying to make adjustments to make things work. Yea, Janome!

I don’t think this machine’s problems are solely a European made vs. Chinese made thing. My machine says it was made in Sweden and it is horrible. I can not believe Pfaff released this machine.

And why when I have the needle down – foot up option selected does the needle not actually go down? About half the time, the needle stays up halfway.

Good grief, I felt this way about the Sapphire 850. I bought it and tried to like it but it just had too many buttons to push and far too much automation. I loved my 2144, but I could turn all of that stuff off. I sold the Sapphire after 7 months and decided that perhaps Viking and maybe Pfaff are not the companies they used to be. I had a Viking #1 and also a #1+ and they were joys to sew on, but the Sapphire was sort of cheap feeling. I did buy the machine because of the large harp and I felt as if I were pulling the quilt around when I tried to free motion quilt. I am a competent FM quilter and that machine was no fun to use. I replaced it with a Bernina 440 that free motions beautifully and is super easy to adjust. Between the foot pedal that raises and lowers the needle and the knee lift that raises and lowers the pressure foot I never have to take my hands away from what I am doing to push a button! I am sorry about every ones troubles and hope they are solved soon.

I am at a loss about all the problems people are having with their machines, I love mine to bits.

As an award winning, professional custom domestic machine quilter and fmq teacher amongst other things I often see skipped stitches on every brand conceivable of machine, and in 90% of the cases it is down to operational error or inexperience- generally its moving the quilt too rapidly for the speed of the machine’s motor or dragging the quilt rapidly and roughly under the needle. Sometimes it is the wrong combination of needle and thread if the student refuses to follow instruction, and sometimes it is not correctly setting up the machine for fmq.

I have been able to achieve skipped stitches on every machine and brand hat has come through a class room I’ve taught in, when handling the quilt wrong, in order to demonstrate what NOT to do! Very few of these machines were terminally ill and needing mechanical adjustment, although a good many needed a good clean out in the bobbin area- which can also produce skipped stitches. I think too often people think if they buy an expensive machine they will automatically become a Dianne Gaudynski or Sharon Schamber just by having a nice machine, and forget they are going to have to learn to adjust it, learn the fmq skills, learn about threads and needle combinations and performances of different battings, to achieve greatness. Even Dianne and Sharon would have experienced a steep learning curve when they began, and have only got so good by practicing the right things for thousands of hours, and by making mistakes, learning what not to do. Both claim the machine is not what is important in good fmq work if you read their books and websites.

Put simply you can’t just throw any combination of threads, battings and fabrics, and needle, plus any range of user experience from novice to professional, at a machine and not have to expect to make adjustments to tension, presser foot choice, pressure foot height and pressure, no matter how cheap or expensive the machine may be.

The new QE range have adjustable presserfeet height in the settings menu (the little tools icon on the front of the machine). If your quilt is very thin you may find it cannot go quite low enough to prevent skipped stitches, in this case use the spring foot. That’s what I did when I had a very thin quilt and had skipping stitches and breakage. Problem completely solved. Use the right foot for the job (along with thread and needle choice compatible with project) and you should get good results if your machine is functioning and you know how to fmq well.

I wonder how many of the unhappy writers above have taken all the free or low cost lessons on machine operation and fmq classes available at their dealer? Most people need time and help to adjust to new machines unless they are working in the industry and exposed to good training-and even then they need play time to get to know the new models coming out.

My machine certainly felt very different to all the others but it is just as capable of producing a perfect stitch in fmq mode as my $8000 husqvarna d1 machine is. And frankly it does nicer stitching than other machines that are more expensive. But then, I am very experienced. I have probably worked out every way to do fmq wrong through trial and error and years of practice! I think user skill has ALOT to do with success with fmq. But it is something everyone can learn, they just need education and practice. It is worth the effort, absolutely.

If you are having ongoing issues I think the best thing to do would be take the machine to the dealer, get the help you need, and see if the dealer can make the machine do as it should with appropriate choices of fabric, batting, needle and thread, and adjustments to machine. If they can’t, then maybe the machine needs servicing or adjustment or replacement if you have been unlucky and received a “lemon” off the production line. You just won’t know if its user error -which probably can’t really be ruled out given you are using a new machine that is less than familiar to you- unless you make the most of the dealers expertise in operating your new machine. Most of us believe we are incapable of error, after all!! lol!

It can be frustrating esp when learning to fmq if you don’t know really what you are doing or need to do for success, so don’t struggle along blindly, getting stressed out. Go and seek help from your dealers and from GOOD fmq teachers that know how to both quilt exceptionally and know how to teach.

I’ve had very few niggles with my machine after purchasing the right foot for the job I was doing. It does almost shudder at really low speeds and thick, thick layers, but so to do other machines I”ve used. A little more speed and that niggle is solved on my machine.

Apart from the feed dog position, which is inevitable on 9mm stitch machines when feed dogs are so far apart, and the impact that has on the design function of the quarter inch foot supplied, and even then there are ways to get the perfect 1/4 inch seam, I find little to complain about.

I love my QE4.0 and know of several people with 2.0 and 3.0 machines – and sapphires for that matter-in my town, that are also very, very happy girls.

How is standard (as in straight, zig zag stitches, etc.) and decreative sewing on this machine? Does it also have these problems or just with fmq?

I’m really unhappy with pfaff expresson 4.0 !!!!

I am seriously considering purchasing the Pfaff Expression 4.0.

I have read the issues several people are having with this machine. Is there anyone who is satisfied with this machine and who would recommend purchasing it?

Like Stephanie, I’m really happy with my machine as well. I did find the same problem with patching (not sewing straight). That’s inevitable for a 9mm machine. I get around it by using the number 0 foot and use the left edge of the feet dog hole as a guide. It works a charm. Free motion wise, it’s great, very quiet and at moderate speed, the foot doesn’t jump up and down, which is very distracting. Once you experience that free motion, the spring-loaded foot becomes quite jumpy for my eyes. And I’m a novice at free motion quilting.

When I first got the machine, I found that I looked forward to quilting every time, which is more positive than what I used to feel like.

I do think that there may be genuine quality control issues with this new line of Pfaff. What other quilters / sewers experienced and their frustrations are genuine. I therefore would advice those who are interested to ONLY buy the machine you’ve thoroughly tested out (not one fresh out of the box and not tried on). I’d bring a quilt sandwich and test out the piecing. The thread cutter needs to be tested also. Ask questions on problems you’ve heard of. I also tried a Husqvarna while I was there.

Hope that helps.

p.s. there’s another lady who loves her machine. Her name is Barbara Strobel Lardon. You can google for her blog. It’s fascinating that there’s such a wide range of experience/opinion on this machine.

Oops, I meant piecing, not patching!

I don’t completely buy that this is a 9mm problem. My 2134 was 9mm and it managed to sew in a straight line.

Hi Dianne, and Ritchie,

I’m really happy with my machine too. The decorative stitches are stunning and stitch perfect. Just be sure to use the appropriate thread and needle and above all stabiliser when using the decorative stitches. What sort and how thick will depend on your project and thread choices.

Depending on the thickness of the thread you can achieve differing degrees of fullness to the design, i.e. Aurifil cotton 50 weight looks almost like embossed work, just beautiful, and finer polyester or rayon embroideries have less height and bulk, great choices for the really detailed designs.

I finally had some time to sit and play and explore all the nice stitches, so far my work on the machine has been straight stitch ditch quilitng really heavy and bulky quilts including ones with lacy and ribbon embellishments that customers bring me to do, piecing patchwork, and loads of FMQ with both sensor and spring free motion foot, depending on the quilt thicknesses and performance under the foot.

I’ve also just made a fitted sheet from fine silk that was purchased by my brother on a trip of a lifetime to China, he lived like the locals for 3 months, shopping and eating as they do- and it was an eyeopener but very rewarding. The machine did not skip a beat handling the slippery silk, very impressed by the stitch quality.

It is a shame that some people have problems with their machine,

When I bought mine I tested the floor stock one and took the one they gave me in the box. But that was before these problems seemed to have emerged. Mine is a Swedish made machine.

I would like to know our of curiosity whether or not the problematic machines were made in Sweden or in China because maybe that would point to different standards of quality control or human error along the line somewhere.

Emily, have you only ever pieced with the machine? I know you have a Grand quilter that you machine quilt with, but have you used the QE4.0?

I think the problem with the quarter inch foot seems to be the design of the foot itself-I find no left pull happens when using the 0 foot-I just set my needle position to 3.0 to the right of centre, a nice scant seam allowance. You could adjust it the other way if you like a full quarter inch in your seaming. The 0 foot is a consistent width down the foot in a way that the new design quarter inch foot is not, so it has better contact with the feed dogs. I think you mentioned you have better luck using the old quarter inch foot from your other Pfaff on the new Qe4.0?

And for those of you thinking about buying it, like Shan suggested, test the actual model you are purchasing, to be sure it will do what you want on the sorts of things you like to sew on. Then there should be no nasty surprises when you get home 🙂

Shan and Stephanie,

I really appreciate your feedback!

Thanks for your suggestions!

I tested this machine twice now and can say that it did really well (in the store anyway). I have a 9mm Bernina and the decorative stitch quality on this Pfaff is actually better, in my opinion. For example, there is a bell stitch that both the Pfaff and Bernina has. I brought the samples home and stitched the Bernina bell stitch next to the Pfaff one. The Pfaff one is much more dense and seems to be crisper using the same type thread. As for the straight, zigzag, and other utitility stitches, the stitch quality seems to be the same as my Bernina. I’m actually thinking of selling my Bernina and gettng this one. Don’t get me wrong, the Bernina is very nice and great quality, but I really like the features on the Pfaff.

I am not happy with the 4.0 either. I have had Pfaffs for 15 years a total of 4 machines. I love the IDt, but with the 4.0 I can’t get it to sew straight with either one of the quarter inch feet. Have had it in for tension adjustment, thread jams, which the tech said he put air to a sensor and it worked after that. He wasn’t able to see the dust, but was probably there from the packing or making of the machine.!!!!. I find it difficult to sew over the corners when doing binding and making the mitered corners. Also when you do a back stitch it takes a stitch forward before it goes back. This messes up the mitered corner. Have used it for decorative stitching and it will see a ways and then just stitch in one place, so will go back for another adjustment. Dealer says the needle bar probably needs to be adjusted and to use a stabilizer. When you are sewing with 2 layers of thin denim and batting I don’t think you need stabilizer. I think the machine is very noisey and especially when sewing on Batik fabric. The thread cutter sometimes cuts the thread. Was told to start a seam, by holding the thread at the back. How are you to get the thread tails, when you can’t even see the bobbin thread to get a hold of it, if you have used the thread cutter? I do not do free motion, since I have a husband that does machine quilting, so he does that for me. RBG Thanks for all the comments, Am glad there are some that are happy. I am glad I only have to go about 25 min. to take my machine for repair, but it is still a pain.!!!

When I was deciding on my next Pfaff to purchase, I was very glad to find this blog site. I’ve been sewing on the 1471 for nearly 23 years and have been very happy with the Pfaff brand. Therefore, when I saw the Pfaff Expressions 4.0, I loved the idea of a larger working area, even though I’m not a quilter. Despite the issues many have expressed, I purchased the machine. I took a printout of this blog site to the Pfaff dealer and showed her all the complaints. We were able to work through most of them. Of course, after sewing on it for a week, I have new questions, but overall I am enjoying the machine. I took home the demo machine, which was made in Sweden. The staff did not know there were some being made in China. After checking their stock, every one (except the one I bought) was made in China.

One problem that Emily brought up was something I was experiencing while sewing clothing…the bottom seam flipping as it passed by the ‘dip’ in front of the bobbin case lid. The solution I came up with was to take a regular piece of paper, cut it about 1-1/2″ x 3″, fold down 1/2″ along a 3″ side and simply slide the folded edge down into where the accessory box meets up with the bobbin case area, which results in a flat surface. I then put a little piece of tape over the remaining 3″ edge. That totally solved the problem of flipped seams. It is a bit odd that an expensive machine needs to have people like me coming up with a solution to a very annoying problem. At least that solved the problem! Also, since I sew garments, I did get the dealer to give me a 5/8″ foot, which I love! They also serviced my 1471, without charge, which I am keeping.

Hi All

I haven’t posted anything on a blog before so apologies in advance if I make any mistakes.

In July last year I decided to return to sewing and learn patchwork and quilting. I wanted to buy a really decent machine as I was worried that I would get one and then realise it didn’t have all the features that I would need.

I have been agonising for ages between the Pfaff QE4.0 and the Janome 6600 and despite the issues detailed on this blog I eventually made my mind up and bought the Pfaff QE4.0 on Tuesday last week. I would like to say a big thank you for all the comments posted – the information here has been very informative and I used it to ‘interrogate’ the dealer before I purchased!

I have to admit I haven’t done much yet apart from read the instruction manual from cover to cover (numerous times!) and try out some of the different functions and stitches. So I am still very much a Learner at the moment, so far so good with what I have tried.

Unfortunately despite all this reading though, I can’t work out how to alter the needle position whilst using the 0 foot for straight stitching. I know I might just be being a bit dim but I have spent ages tonight trying to find the instructions for how to do this (in the manual and online).

I see that a couple of you have recommended this to help get around the issues with the 1/4″ foot that comes with the machine and wanted to test your recommendations but have been unable to as yet!

I would be very grateful if someone could help!

Many thanks in advance.

Tracy

Hi Tracy, When you are sewing a straight stitch and you change the width it will change the needle position. I hope this helps.

JO

Hi Jo

Thank you very much for your reply. I have just tried it and will now hold off on buying a new 1/4 ” foot and use the standard one and alter the needle position to give me a 1/4″ seam and see how that goes.

Thanks again

Tracy

I would appreciate advice from those of you who are experienced FMQ. I bought the Pfaff Expression 2.0 for the express purpose of machine quilting. I like the idea of the other “quilting” features – the long arm, IDT – so I thought this was the right machine for me. When I tried to FMQ the first time, I found that the bobbin thread floated on the underside of the fabric, so I changed the tension. I had to set the tension to 7.5 in order to get a decent stitch. I am concerned that if I have to set the tension that high for this simple procedure, will I be able to use decorative or invisible threads in this machine. Some more facts:

I am very new to FMQ – I have taken 1 brief course, and realize that I don’t know much about FMQ.

I put a new needle, size 80 (also tried 90) in the machine, used the thread recommended at my quilt shop, used high quality fabric and batting. Technicians at the quilt shop have worked on the machine 2 times, both times telling me that it worked just fine. The 2nd time the technicians worked on it, it took them over 1 1/2 hours to make the adjustments.

Should I feel like this machine is okay, and the reason I am having problems sewing on it is because I’m new to FMQ, or does it sound like there’s a problem with the machine?

Thanks in advance for all advice.

I purchased a QE 4.0 and have had it in and out of the shop for many repairs that have to do with thread jams and the cutter jamming up. The shop repairman said that they are awaiting parts to be shipped from the factory and that Pfaff is being very difficult to work with. I really regret this purchase.

I notice new to commenting people have to mention it and I understand that as this is the first time I have every written anything on a blog. I bought my Pfaff 4.0 with fab o motion the end of december 2008. I looked on the web and couldn’t find any comments one way or another so bought it. I have weak wrists and some arthritis so thought this was the way to go as the f.o.m. makes moving the quilt so much easier. In fact I have a Bernina with stitch regulator and just couldn’t move the fabric to my satisfaction. So a few days ago I found this site and started reading all the comments. I was having all of the problems that have been mentioned and I didn’t know it was a product of China, either. Which bothered me a bit. But Stephanie was very calm and logical and I really took her comments to heart. I made some notes to myself about reducing tension. lowering presser foot pivot height and the needle size. Speaking of the needle size, a friend told me she always uses a size 16 needle. I had tried different types and sizes but none that big. I just finished a medium size quilt which has all my mistakes, skipped stitches but my feathered borders are beautiful and I know its because of those three things I adjusted and changed. Tension, pressor foot and size 16 needle. Also I think I was moving too fast. The f.o.m moves so easily. Right now today I love it and am happy I bought it. I’ll let you know more as I quilt many of my ufo.

Rosemary

I had a Pfaff 2044 for many years and never experienced any problems with it – I loved it. I decided to upgrade to the Expression 4.0 solely for the larger space to the right of the needle.

I have only had my machine for 3 weeks and it is already back at the dealers.

It has had intermittent problems from the first day I got it. “Motor overload” when piecing cotton at medium speed, “thread jam” error when there were no thread jams, flaky stitch length, the tension not seeming to change and the same problems others have had.

On Sunday it stopped working properly at all, with the needle “jumping” sideways every few stitches. Nothing triggered this – one day it was fine, the next it wasn’t.

I really feel there must be a quality control issue somewhere – those who have good machines that work properly seem really happy with their machines. Those of us with problem machines seem to have LOTS of problems!!